Market product production

Production Process

NPM Group flowchart

1. Admin Coordinator

2. Engineering System

3. Quality Assurance

4. Delivery

NPMc

Production process (Cast Iron casting)

1. Material Received

2. Production

2.1. Core Making

2.2. Green Sand Mould Making

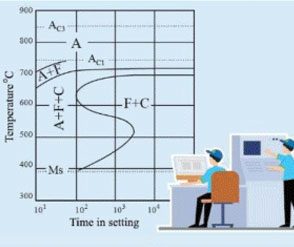

2.3. Melting Process

3. Inspection Process

3.1. Chemical Composition

3.2. Mechanic and Physical Property

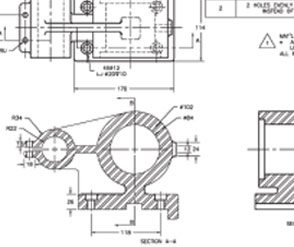

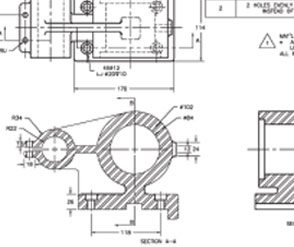

3.3. Dimensional

4. Delivery

TMT

Production Plan (Machining)

1. Material Received

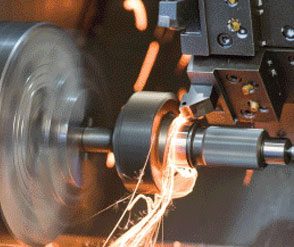

2. Machining Process

3. Inspection Process

4. Final Inspection

5. Delivery

YMT

Production Plan (Aluminium Gravity Casting)

1. Material Received

2. Production

2.1. Aluminium Melting Process

2.2. Pouring Die & Machine Preparation

2.3. Pouring Process

3. Heat treatment: T6 process

4. Inspection Process

4.1. Chemical Composition

4.2. Mechanic and Physical Property

4.3. Dimensional

5. Delivery

Machinery and Material

NPMc (Iron Casting)

Main business : Grey cast iron, Nodular cast iron, and Alloy cast iron for:

- Automotive Parts

- Agricultural Parts

- Electrical Parts

- Other Cast Iron Parts

Main materials

- FC All Grade

- FCD All Grade

- FCD Hi Si-Mo & Special Alloy Cast Iron

Machine and production facilities

- Coreless Induction Furnace

- 3 Tons x 2 Crucible

- 6 Tons x 2 Crucible

- Ladles (capacity: 500 kg)

- Pouring Machine

- Automatic Moulding Machine (Sinto FCMX III)

- Shell Core Machine

Chemical Analysis Apparatus

- Optical Emission Spectrometer (OES) 28 elements

- CE Metre

- Temperature Monitoring

TMT (Machining)

Main business: Machining parts for:

- Automotive Parts

- Agricultural Parts

- Electrical Parts

- Other Machining Parts

Machine and production facilities

- Machining centre = 29 units

Type:- Horizontal

- Vertical

- Machining Lathe = 31 units

Type:- Horizontal

- Vertical

- Multifunction

- Special Machine

- Horning Machine Surface

- Balancer machine 4 machine

- Others

YMT (Aluminium Gravity Die Casting

- Automotive Parts

- Agricultural Parts

- Electrical Parts

- Other cast aluminium and core sand making

- AC2B

- AC2A

- AC4DS

- Others: according to the customer’s requirement

- Automatic Pouring Line (Robot) & Manual Line

- 9 Pouring Machines (designed according to the size of the part)

- 300 kg melting furnace 2 furnace

- 600 kg melting furnace 2 furnace

- 500kg Holding Furnace 2 furnace

- 4 Heat Treatment Furnace

- Optical Emission Spectrometer (OES) 28 elements for Aluminium

- Automatic Visual Inspection Machine

NPMG Quality Laboratories

- Chemical Composition Analysis

- Microstructure of casting by software

- FC & FCD analysis by software

- Tensile Strength & Elongation

- Hardness test (Brinell, Rockwell, etc.)

- Green sand properties lab

- CMM machine

- Contour machine tester

- Roundness tester

- Roughness tester

- Small tools tester

- 3D part and gating design

- Casting simulation

- Machine simulation

- 3D printer rapid prototype

- 3D scanner dimension compares CAD/CAM